Razor Blades

Our blades are the result of high-tech manufacturing processes in complex work processes, controlled by experienced personnel.

We offer blade production in different sizes and in 5 different designs to guarantee the best cutting result for your work.

Our

Finishes

ICE CUT

is an improved coating so that the cut edges are additionally protected with an extremely hard coating, which increases wear resistance and reduces friction with the film.

CARBO CUT

is a hard ceramic coating and is applied to industrial blades to reduce friction on the blade surface and strengthen the cutting edge against premature wear.

DIAMOND CUT

is a very hard and durable diamond coating with an ultra-fine lapped surface to ensure maximum durability and precise and sharp cutting edges. It is designed to ensure long service life and reduce machine changes

TUNGSTEN

Blades are used for slitting very abrasive material and even if it is sheet material, the solid micro-grain saw blade could be the right choice for optimal results. In this family we offer two types of blades.

CERAMIC BLADES

are significantly harder than steel blades, do not corrode in harsh environments and do not conduct electricity at room temperature. They are resistant to strong acids and corrosive substances and do not rust. The sharpness of the cutting edge is retained for longer.

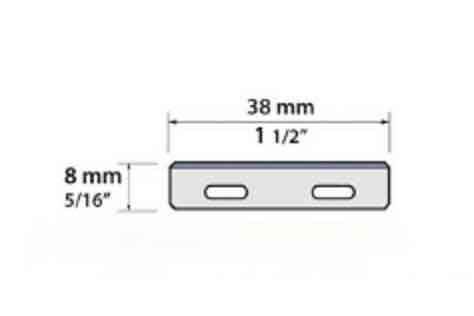

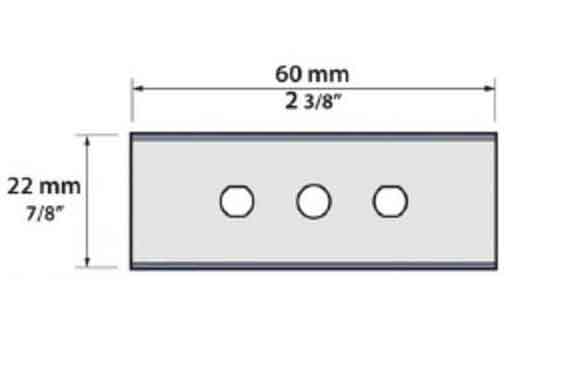

Modell 1

Available Thickness: 0,25 mm

Available Finish: Ice Cut, Carbo Cut, Diamond Cut

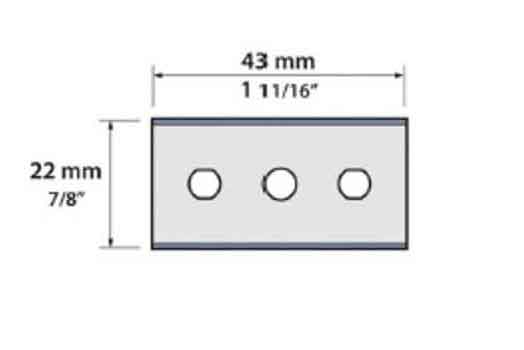

Modell 2

Available Thickness: 0,10 mm, 0,20 mm, 0,30 mm

Available Finish: Ice Cut, Carbo Cut, Diamond Cut, Tungsten, Ceramic

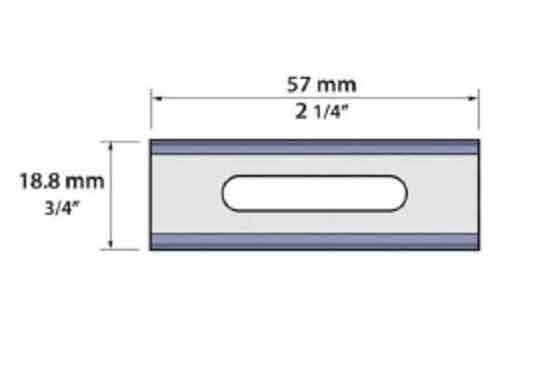

Modell 3

Available Thichkness: 0,40 mm

Available Finish: Ice Cut, Carbo Cut, Diamond Cut, Tungsten, Ceramic

Modell 4

Available Thickness: 0,20 mm, 0,30 mm

Available Finish: Ice Cut, Carbo Cut, Diamond Cut, Tungsten, Ceramic

Any Questions?

Contact us!

High quality services. We attach great importance to detailed, personal and complete service. We are committed to satisfying our long-term customers and ensuring that our products are of superior quality.